Case Studies

Revolutionizing Industries with 3D Printing

3D printing transforms spare parts, aviation structures, automotive molds, and special tools with on-demand customization, cost savings, and rapid prototyping. Ideal for enhancing performance and efficiency across various sectors.

Spare Parts

- 3D printing produces spare parts with benefits like on-demand customization, reduced inventory, and cost savings. It supports rapid prototyping and intricate designs, with applications in automotive, aerospace, and medical fields. Considerations include material choice and design accuracy.

Aviation Structures

- 3D printing enables the creation of lightweight, complex UAV and Drone structures and accessories, optimizing performance and efficiency. It allows for rapid prototyping and customization, reducing costs and lead times. Key considerations include material strength and component precision.

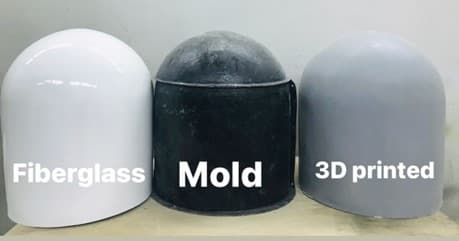

Automotive/Customized Molds

- We able to print end use products, like automotive and customized molds such as fenders, use 3D printing for highly customized designs, rapid prototyping, and cost-effective low-volume production. This method supports complex geometries and quick adjustments. Applications include automotive parts and prototyping, with considerations for material durability, design accuracy, and post-processing. 3D printing offers a flexible and efficient solution for specialized molds and parts. The dome anti drone is printed with large scale , then fiberglass molds are made and low quantities are manufactured by moldes.

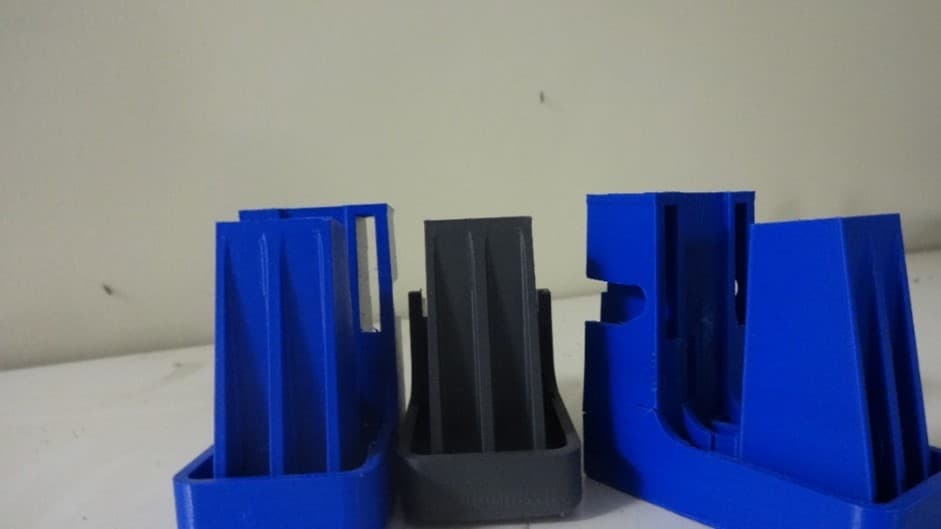

Automotive/ Aerospace Special Tools

- The ability to create complex parts, rapid prototyping, and cost-effective production for low volume or custom designs. Metal 3D printing supports applications requiring high strength and performance, making it suitable for critical automotive and aerospace parts as well as specialized tools. Key considerations are material properties, design accuracy, and post-processing requirements.